Capitalizing on unique ceramic technology to

drive technological innovation

Home | Business Fields | Electronic Components

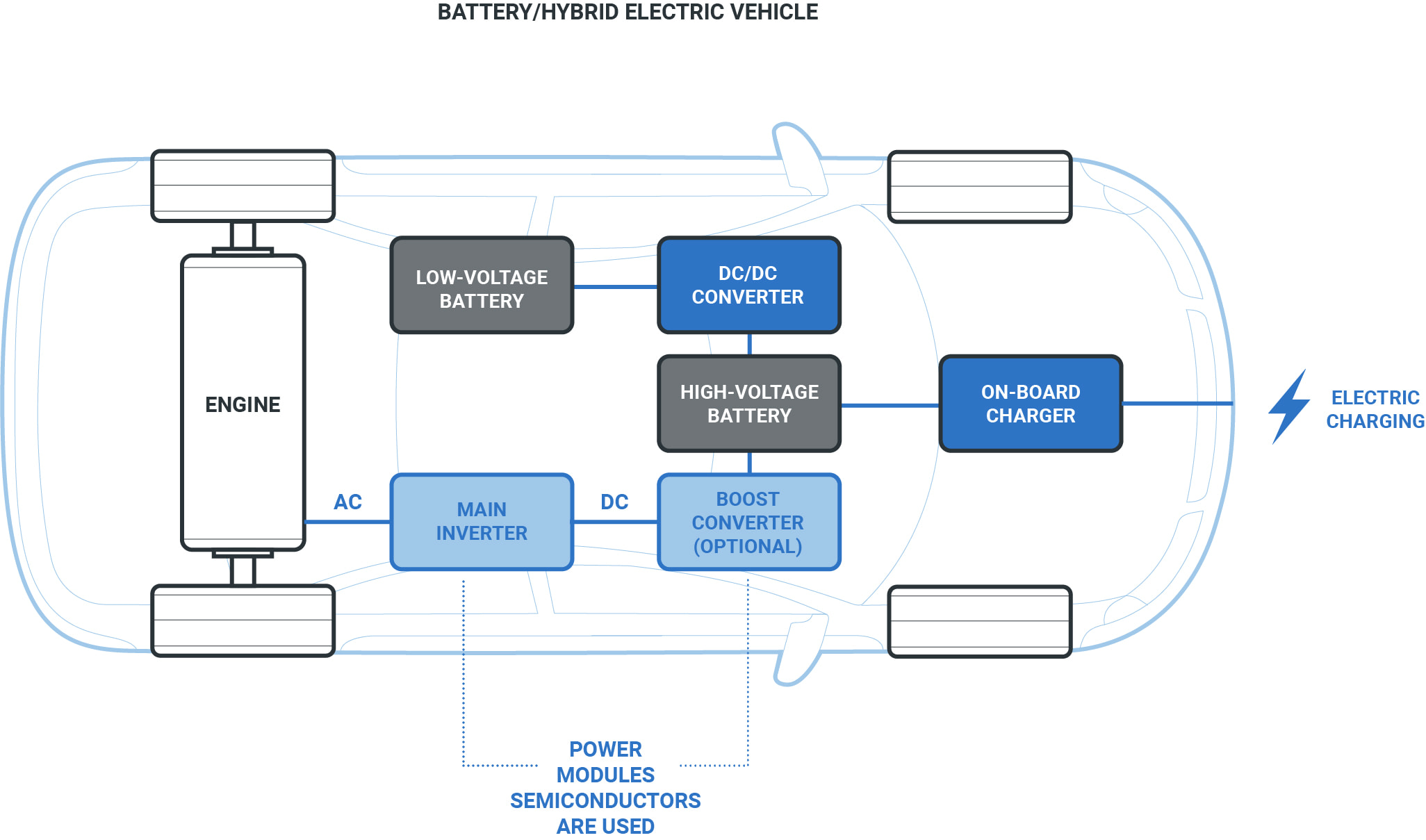

NGK’s proprietary high-precision ceramics technologies contribute to advances in electronics. Applying our proprietary ceramics technologies, we can supply various products such as piezoelectric microactuators, high frequency components and mold-cast ceramics, but within NGK Europe we are also specialized on the products of DCB and AMB Ceramic Substrates for Power Module / Power Semiconductor applications.

NGK’s Direct Copper Bonded (DCB) substrates are based on both 96%-Al2O3 and ZDA (ZrO2(10-20%) doped alumina) bare ceramic substrates, directly bonded with copper on both sides – through a single step bonding process.

NGK’s Active Metal Brazing (AMB) substrates are based on silicon nitride (Si3N4) ceramic. In addition to the existing DCB products, the copper on both sides is bonded using a brazing material within NGK’s unique process, which achieves ultra-thin boding layer for superior thermal-cycle durability and isolation reliability.

Further details can be found on our website.

NGK developed its own DCB technology – starting with raw material development (ceramic bare master-cards) to the finished substrates. In order to provide the highest level of quality requirements and product performance, our patented DCB substrates are further toughened by adding ZrO2 to the conventional Al2O3 thereby achieving higher ceramic strength and thermal characteristics.

Thick copper plate (>0.2 mm) can be bonded on ceramic bare substrates with both DCB and AMB technologies in order to achieve high insulation durability against large electric current flow and thus provides excellent insulation and higher cooling performance. Therefore, it enables the substrates and reduces thermal resistance (Rth), resulting in higher heat dissipation efficiency for power module applications.

(Ref.) Yole Development market report

(Ref.) Yole Development market report